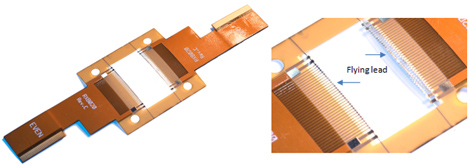

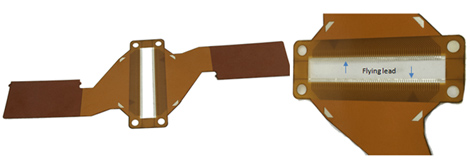

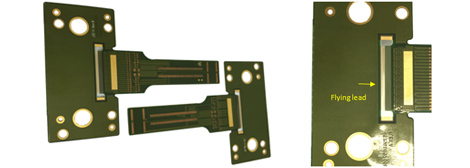

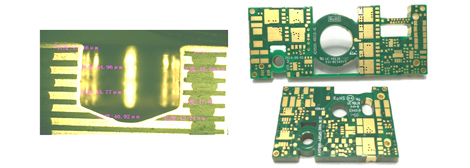

Flying Lead FPC

- Double Side

- 5.12 mil line / 4.72 mil space

- Hard Gold @ ZIF / Tin @ flying lead

- Double Side

- 5 mil line / 4 mil space

- Hard Gold @ ZIF / Tin @ flying lead

- Multi Layer (3 layers)

- 2 mil line / 2 mil space

- Soft Gold @ flying lead / Soft ENIG @ component area & exposed area

- Blind via

- Double Side

- 2.36 mil line / 2.36 mil space

- Hard Gold @ ZIF / Tin @ flying lead

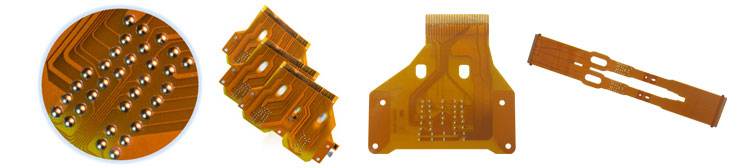

FPC with Dimple

- Double Side, Single Side

- Electrolytic Nickel & Hard Gold Plating

- Dimple height max 0.05mm

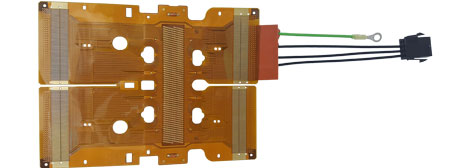

FPC with Heater

- Double Side

- 4 mil line / space

- ENIG

FPC with Metal

- Single, Double, Multi-layer

- Stainless steel, Aluminium

FPC with Plastic

- Single, Double, Multi-layer

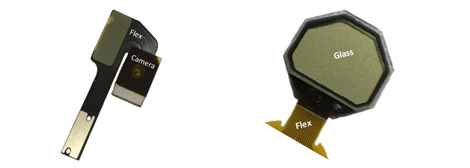

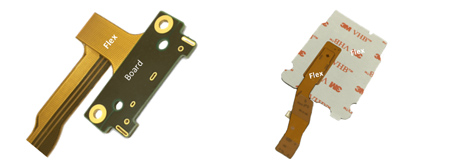

Type of Conductive Bonding

- Camera Module bonding on Flex

- Flex bonding on Glass

- Flex bonding on Board

- Flex bonding on Flex

Various Type of Component Assembly

We offer a one stop turnkey assembly service which include :

- Switches

- Mic

- Camera socket

- LED

- Microphone

- Filter

- Diode

- Varistor

- Thermistor

- Receiver

- Sensor

- Beeper

- Transformer

- Resistor

- Capacitor

- Heater

- Speaker

- Relay

- FET (Field Effect Transistor)

- Phototransistor

- Jumper

- Proximity Sensor – IC

- Hall switch sensor – IC

- EEPROM – IC

- Triac

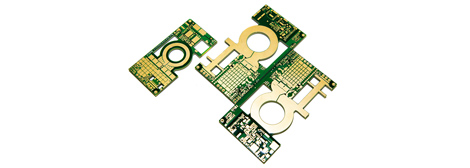

PCB

- Heavy copper PCB up to 10oz copper and up to 32 layers

- Embedded copper coin technology for heat dissipation, thermal simulation & reliability

- 2.5D cavity to enhance PCB thermal management, reduce overall thickness of an assembled device by recessing “thick” component

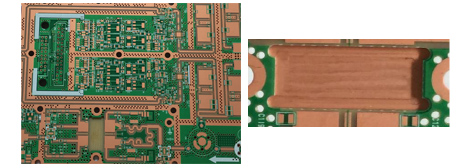

Heavy Copper PCB

Rigid PCB

- 10oz copper thickness

- up to 24 layers

- Inner Layer with blind via

Heavy Copper PCB

- up to 32 layers

- Depth control drilling & milling

- Impedance control ±10%

Embedded Copper Coin PCB

- Embedded I Coin

- ENIG Finishing

- Coin Inner Flatness Control <30um